Tuesday, April 12, 2011

Monday, April 11, 2011

Descriptive Geometry Notes

Manipulating(rotate) picture planes(surfaces) in order to identify:

PDMODE=96

PDsize=.1

TSS

- TSize

- TShape

- TLength

- Tangle

- Intersection

- Distances

- If a line is parrallel to a fold line in one view, it is true length in the next

- First find TL o fline

- Create fold line perpindicular to the TL line

PDMODE=96

PDsize=.1

TSS

- First find TL of one line

- Create a fold line perpindicular to the TL line to get the edge view(EV) of the surface

- Create a foldline parallel to edge view

- Draw a line parrallel to F1 from 1 point to the line you want TL of

- Project the point where it hits the line you want TL of to the next view on the same line

- Connect that point to the point you started with wich gives you a TL line

- create FL perpindicular to TL which will give you your EV including a point

- Create FL parrallel to EV which will give you your TSS surface

Monday, February 28, 2011

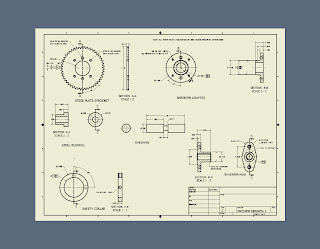

Dimension Notes

- ANSI standards

- no arbitrary

- standard way of positioning dimensions, why?

- describe size

- locate details

- For convienence for manufactor

- No calculations necessary

- no duplications

- 1st 3/8 of an in. (9mm) from the object line should be

- lines and symbols inside extension lines if possible

- Extend from object but 1/16 inch (2mm) gap between object and extension line

- Scale=Dim. scale

- runon angle so obvious not part of drawing

- 1/4 inch tail

- arrow if to edge, dot if to surface

- crosss few lines

- any<except horizontal or vertical

- don't pass through corners

- First big 3 H,W,D

- in between viewws if possible

- off view where detail is best described

- do not dim from a hidden line

- locate from common corner

- smallest dim closest to object

- no calc.

- no duplications

- Draw at same angle as object being dim

- use degree symbol %%D

- ARC-anything less then full circle dimas radius

- circle always diam %%C

- Cylinder-in profile (side) view

- hole-where it shows as a hole

Tolerances

- Hold precise tolerances for interchange ability

- how much a dim can vary

- Basic size- exact size

- Tolerance- amount a dim can vary from basic size

- feature-identify geometry

- limits of size- max or min from exact size

- allowance-limits where smallest clearance of largest interference occurs measured at mmc

- limit of a dim where the max material is left on the part

- limit of dim where least amount of maaterial is left on part

- Types of fit

- Clearance-space between parts

- Interference- force fit

- Transition-diff combos, diff fits

Auxiliary Views

- Sometimes you needd more then 3 views

- seconday view used to show true size and shape (TSS)

- perpindicular to recommended surface

- TSS when its edge is parallel to the fold line

- SKIP A VIEW MEASURE BACK

Subscribe to:

Comments (Atom)